58 in stock

Features

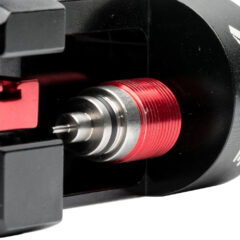

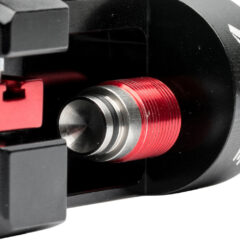

- designed for pressing threaded and barbed fittings into hydraulic brake hoses

- works with Jitsie, Magura, Hope, and other trials/MTB brake systems

- provides straight, controlled installation for leak-free performance

- prevents hose deformation or internal damage during fitting

- machined aluminium construction for durability and precision

- compact, easy-to-use bench or handheld design

- essential tool for professional workshops or riders maintaining their own brakes

Description

The Jitsie hydraulic brake hose fitting press is a precision workshop tool designed to install barbed fittings into hydraulic brake hoses quickly and accurately. Whether you’re working on trials or mountain bike brake systems, this tool ensures a perfect fit without damaging the hose — ideal for Jitsie, Magura, Hope, or similar hydraulic setups.

How To Guide

Step-by-step:

1. Prepare the hose

- cut the hose square and clean with a sharp cutter

- wipe the end with isopropyl alcohol

- slide the shroud nut onto the hose first (threads facing the master cylinder), then add the olive, and finally the barbed fitting

2. Set up the press

- place the hose in the tool’s cradle with the cut end aligned

- insert the barbed fitting into the press nosepiece

- (optional) apply a tiny drop of brake fluid to the barb for easier pressing

3. Press the barb

- close the tool and tighten smoothly until the barb seats flush with the hose end

- don’t over-press; stop once it’s fully inserted and straight

4. Finish the assembly

- slide the olive forward against the hose end

- thread the shroud nut into the lever or caliper by hand, then tighten to the brand’s torque spec (≈ 4–6 Nm)

- ensure the hose sits straight while tightening

5. Check and bleed

- pull lightly on the hose — it should not move

- wipe clean and perform a system bleed if needed

- re-inspect after first use to confirm there’s no fluid weep

Tips:

- always use the correct hose, fittings, and fluid for your brake brand

- a clean, square cut = reliable, leak-free connection

- keep DOT and mineral oil components completely separate

Fast shipping from Belgium with SendCloud

Easy 30-day returns

Secure checkout with Stripe or PayPal

Rider-tested, competition-proven products

Support from people that ride and know trials